Centrifugal Electric Hydraulic Submersible Slurry Pump Gravel Pump Sand Pump Mud Pump for Sand Dredging with Agitator Cutters

The ZJQ submersible slurry pump is a hydraulic machine in which the motor and the water pump are coaxially submerged int

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | ZJQ |

| Working Pressure | Low Pressure Pump |

| Influent Type of Impeller | Single Suction Pump |

| Position of Pump Shaft | Vertical Pump |

| Pump Casing Combined | Verticaljoint Surface Pump |

| Mounting Height | Suction Centrifugal |

| Impeller | Semi-Open |

| Usage | Pump, Pumps, Condensate Pump, Ash Pumps, Circulating Pump |

| Transport Package | Seaborne Wooden Cases |

| Specification | 2502kg |

| Trademark | shenlan |

| Origin | China |

| Production Capacity | 8000 Sets/Year |

Product Description

The ZJQ submersible slurry pump is a hydraulic machine in which the motor and the water pump are coaxially submerged into the medium.It is suitable for conveying liquids containing solid particles such as sand, coal slag, tailings, etc. It is mainly used for the removal and transportation of slurry liquids in metallurgy, mining, thermal power plants and other enterprises. It is an ideal substitute for traditional mud pumps.

In addition to the main impeller, a set of stirring impellers are added to the bottom of the pump, which can spray the deposited sludge into turbulent flow. The pump can achieve high-concentration transportation without auxiliary devices.

The operating reliability of the unique sealing device greatly extends its service life. The electrode adopts overheat protection, and various protection devices such as near-water detection can be added according to user requirements, which can operate safely under severe working conditions.1. The motor is protected by a mechanical seal, which can effectively prevent high-pressure water and impurities from entering the inner cavity of the motor.

2. In addition to the main impeller, there is also a stirring impeller, which can stir the sludge deposited on the bottom of the water into a turbulent flow and then extract it.

3. The main flow parts such as impeller and stirring impeller are made of high wear-resistant materials, which are wear-resistant, corrosion-resistant, non-clogging, and have strong sewage discharge capacity, and can effectively pass larger solid particles.

4. It is not limited by the suction range, the slurry suction efficiency is high, and the silt dredging is more thorough.

5. There is no need to equip auxiliary vacuum pump, so the investment is lower.

6. There is no need to be equipped with auxiliary stirring or spraying devices, making the operation easier.

7. The motor is submerged under water, no complicated ground protection and fixing devices need to be built, and the management is easier.

8. The stirring impeller directly contacts the deposition surface, and the concentration is controlled by the depth of the dive, so the concentration control is more free.

9.The equipment directly dives into the water to work, there is no noise and vibration, and the site is more tidy.

| Applications |

With small size and light weight, the QDX/QX Series pump is especially suitable for the rural wells water pumping, the farmland irrigation and drainage, garden watering, water spraying and households water supply, as well as other applications such as industry, aquaculture, construction sites and many other commercial applications.

| Features |

2. Portable and durable aluminum alloy structure.

| Operating conditions |

Liquid PH: 6.5-8.5

Maximum liquid temperature: +40ºC

Maximum ambient temperature: +40ºC

Maximum immersion depth: 5m

Maximum sand content: 0.1%.

The grain diameter of suspended solids up to 0.2mm

| Motor and Pump |

Protection class: IP68

Pump body: Cast aluminum

Motor bracket: Cast iron.

Impeller: Aluminum alloy or plastic impeller

Motor shaft: The heat treated steel shaft

Mechanical seal: Ceramic-Graphite, Silicon Carbide-Carbide alloy.

Copper winding

2-pole induction motor.

Single-phase:220V-240V/50Hz

Three-phase:380V-415V/50Hz

Single-phase with capacitor and thermal overload protection.

| Optional available on request |

Single phase can add float switch

Other voltages or frequency: 60Hz

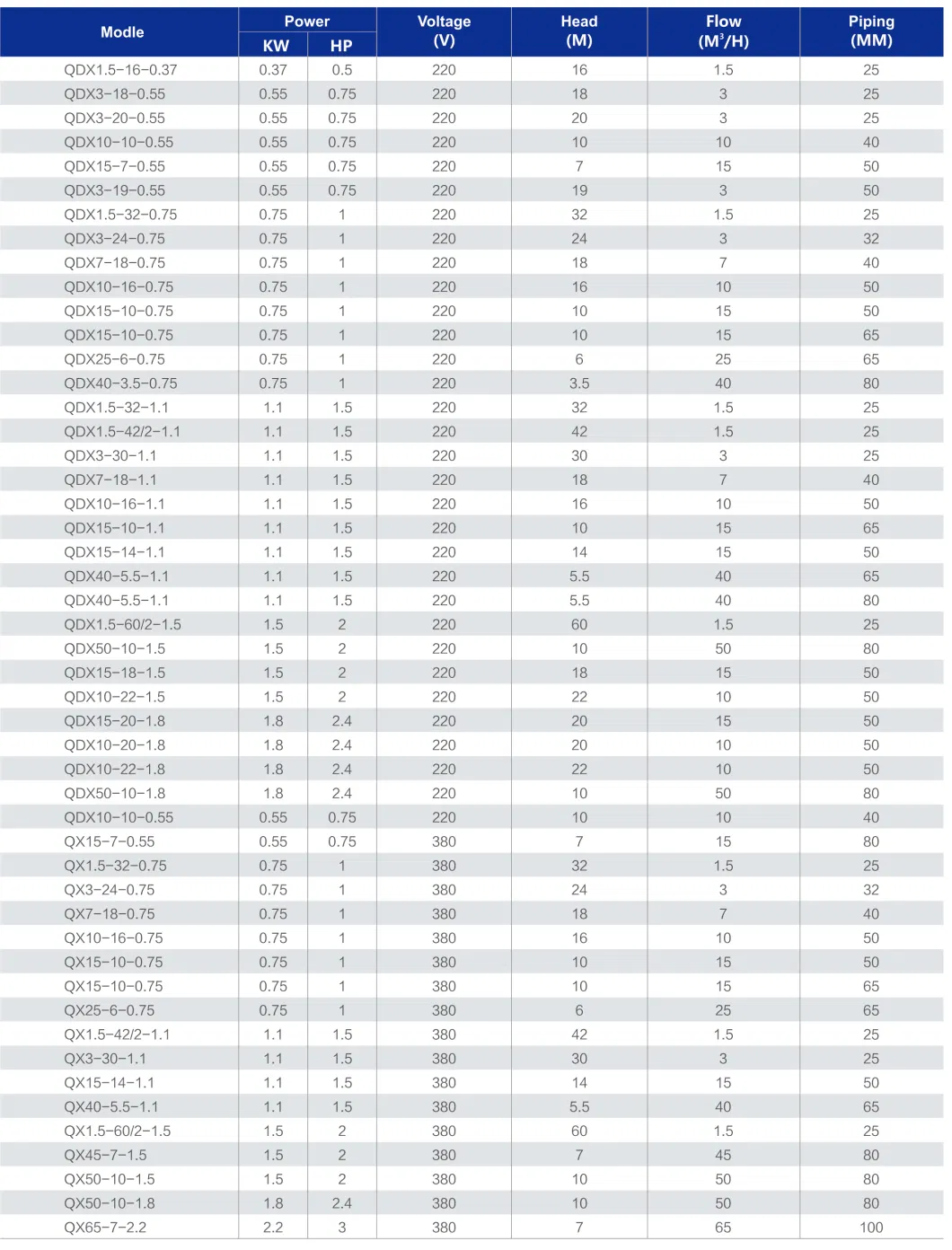

| Technical Parameter |

Structure Chart |

Hebei Shenlan Pump Valve Co., Ltd. is a modern water pump company specializing in production, research and development, sales, and service. We have been engaged in the centrifugal pump industry for over 20 years. We have a modern standard pump room and a processing workshop with various advanced processing equipment. The entire process from casting to assembly is a one-stop closed-loop production. A team of experienced production and R&D engineers is professional and efficient. Choose us, a professional team, professional equipment, and trustworthy.